Meshes in Austria

Table of content

The product

The BSTG facilities of the Pittini Group, based in Graz and Linz, are devoted to manufacturing electrowelded meshes especially for Austria and Germany, thus ensuring comprehensive commercial and technical support as well as high quality products thanks to continuous investment in plants made to achieve the highest technological standards.

Download technical sheet Meshes

The standard electrowelded meshes produced in Osoppo obtained the EPD Certification – Environmental Product Declaration – by the certifying partner ICMQ, the Institute for certification and quality branding for products and services for construction.

BSTG also specialises in the design and supply of customized electro-welded wire meshes for the Austrian market.

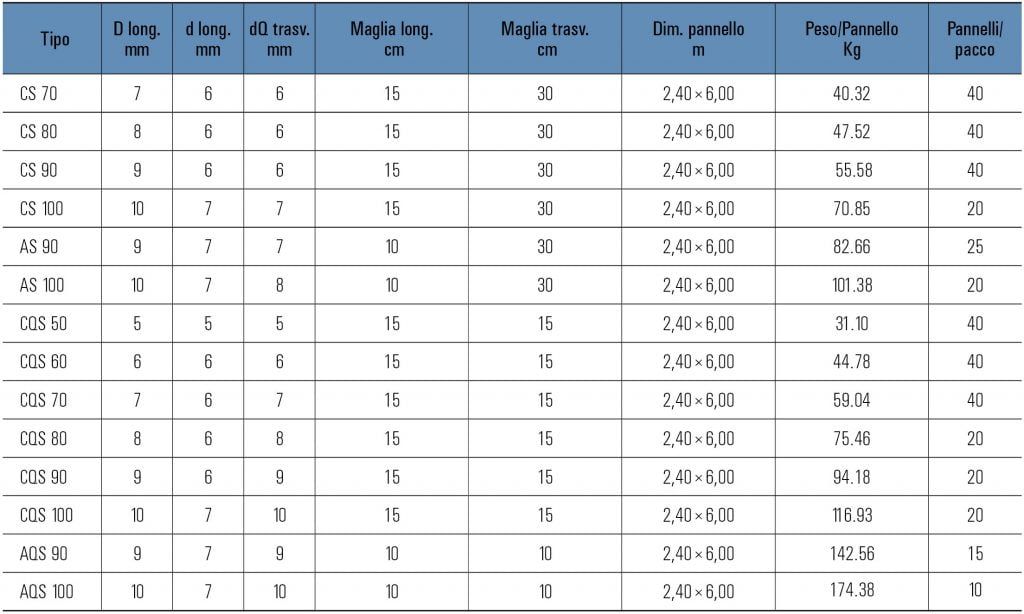

Characteristics

Electrowelded wire mesh is used to strengthen reinforced concrete structural elements. Electrowelded wire mesh is manufactured in compliance with the ÖNORM B4707 standard.

On account of its mechanical and technological characteristics, electrowelded wire mesh is classified as a B550A wire mesh pursuant to the ÖNORM B4707 standard.

|

Yield strenght |

Re ≥ 550c N/mm² |

Ratio/Yield strenght |

Rm/Re ≥ 1,05c |

Total elongation |

Agt ≥ 2,5c % |

For Diameter of 5.0 mm to5.5 mm applies: |

Rm/Re ≥ 1,03c Agt ≥ 2c % |

|

For diameters less than 5.0 mm, no evidence is required. |

|

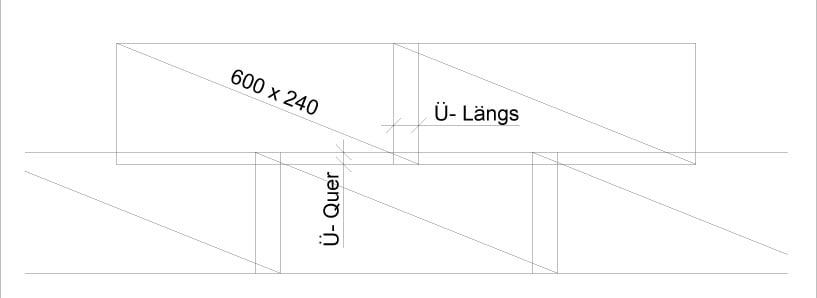

Lenght: 6,00 m standard

Width: 2,40 m standard

Standard Meshes A/AQ

| Mesh Type | Ø long. |

Ø trasv. |

Mesh long. |

Maglia trasv. |

Panel Dimension | Weight/panel | panel/pack |

| [mm] | [mm] | [cm] | [cm] | [cm] | [kg] | ||

AQ 42 |

4.2 | 4.2 | 10 | 10 | 240×600 | 31.39 | 50 |

AQ 50 |

5 | 5 | 10 | 10 | 240×600 | 44.35 | 50 |

AQ 55 |

5.5 | 5.5 | 10 | 10 | 240×600 | 53.86 | 50 |

AQ 60 |

6 | 6 | 10 | 10 | 240×600 | 63.94 | 25 |

AQ 65 |

6.5 | 6.5 | 10 | 10 | 240×600 | 74.88 | 25 |

AQ 70 |

7 | 7 | 10 | 10 | 240×600 | 86.98 | 25 |

AQ 76 |

7.6 | 7.6 | 10 | 10 | 240×600 | 102.53 | 25 |

AQ 82 |

8.2 | 8.2 | 10 | 10 | 240×600 | 119.52 | 20 |

AQ 90 |

9 | 9 | 10 | 10 | 240×600 | 143.71 | 10 |

AQ 100 |

10 | 10 | 10 | 10 | 240×600 | 177.70 | 10 |

A 60 |

6 | 5 | 10 | 30 | 240×600 | 39.36 | 50 |

A 70 |

7 | 5.5 | 10 | 30 | 240×600 | 52.46 | 50 |

A 82 |

8.2 | 6.5 | 10 | 30 | 240×600 | 72.24 | 25 |

Technical drawing

Technical drawing Type AQ

Technical drawing Type A

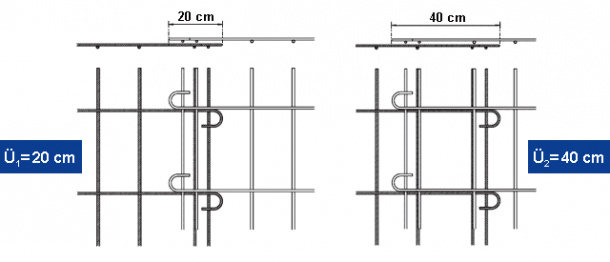

Schlaufenmatte ÖMAT Meshes

ÖMAT electrowelded wire mesh is an improvement over standard wire meshes due to the presence of hooks at the ends, which offer the following advantages:

- The special overlapping system with hooks makes laying simpler and ensures quick and safe site control.

- Reduced use of steel in overlapping areas thanks to single overlaps with hooks of just 20 cm.

- Lower weight thanks to lighter edges.

- Increased profitability thanks to the availability of 2 standard lengths of 5.10 m/6.00 m/7.20 m, respectively, for meshes type AS, CQS and AQS.

- Simple and safe handling of meshes thanks to the presence of hooks.

Special lengths: 5.10 m / 7.20 m per AS 90, AS 100, CQS 70, CQS 80, CQS 90, AQS 90, AQS 100

Other special lengths upon request.

Examples

|

Example 1 |

AQ 65 |

ÖMAT CQS 80 |

Steel cross-section |

3.32 cm²/m |

3.35 cm²/m |

Mesh length/width |

6.00 m x 2.40 m |

7.20 m x 2.40 m |

Mesh weight |

5.20 kg/m² |

5.24 kg/m² |

Longitudinal overlapping/transversal overlapping |

34 cm / 34 cm (zB. Beton B25) | 42 cm / 20 cm (Schlaufenstoss) |

1 mesh panel covers a surface of |

(6.00-0.34)*(2.40-0.34)=11.66 m² |

(7.20-0.42)*(2.40-0.20)=14.92 m² |

Average steel requirement |

5.20*6.00*2.40/11.66=6.42 kg/m² |

5.24*7.20*52.40/14.92=6.07 kg/m² |

|

105.80 % |

100 % |

|

|

Example 2 |

AQ 90 |

ÖMAT CQS 90 |

Steel cross-section |

6.36 cm²/m |

6.36 cm²/m |

Mesh length/width |

6.00 m x 2.40 m |

6.00 m x 2.40 m |

Mesh weight |

9.98 kg/m² |

9.90 kg/m² |

Longitudinal overlapping/transversal overlapping |

48 cm / 48 cm (zB. Beton B30) | 48 cm / 20 cm (Schlaufenstoss) |

1 mesh panel covers a surface of |

(6.00-0.48)*(2.40-0.48)=10.60 m² |

(6.00-0.48)*(2.40-0.20)=12.14 m² |

Average steel requirement |

9.98*6,00*2.40/10.60= 13.56 kg/m² |

9.90*6.00*2.40/12.14= 11.74 kg/m² |

|

115.5 % |

100 % |

Laying method 1:

Overlappings1: 20 cm

Laying method 2:

Overlappings2= 40 cm

The choice between method 1 or 2 depends upon the mesh cross-section and the way it is cut taking into account economic criteria.

Mechanical and size characteristics of meshe B550A

| Standard | Ø [mm] |

Weight tol. [%] |

Re min [MPa] |

Rm/Re min |

Re/Rm,nom max |

Agt min [%] |

Rt min [%] |

Bend α,k |

PITTINI |

4.2 ÷ 10 | note | 550c | 1.05c | 1.3 | 2.5c | 30c | 180,8 |

ÖN B 4707 |

3 ÷ 12 | note | 550c | 1.05c | 1.3 | 2.5c | 30c | 180,8 |

REMARKS:

– C characteristic val.

– Tests after artificial aging at 100°C/1h

– Weight tolerances: ± 4.5% for diameters larger than 8 mm; ± 6% for diameters up to 8 mm

Mechanical and size characteristics of meshes B550B

| Standard | Ø [mm] |

Weight tol. [%] |

Re min [MPa] |

Rm/Re min |

Re/Rm,nom max |

Agt min [%] |

Rt min [%] |

Bend α,k |

PITTINI |

6 ÷ 10 | note | 550c | 1.08c | 1.3 | 5c | 30c | 180,8 |

ÖN B4707 |

3 ÷ 12 | note | 550c | 1.08c | 1.3 | 5c | 30c | 180,8 |

REMARKS:

– C characteristic val.

– Tests after artificial aging at 100°C/1h

– Weight tolerances: ± 4.5% for diameters larger than 8 mm; ± 6% for diameters up to 8 mm

Gallery

Sales Organization

A continuous and reliable service is guaranteed by Pittini Group’s Sales Department.

Contact our designated representative: