Meshes in Italy

Table of content

The product

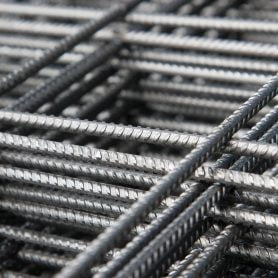

The industrialisation of reinforcements has led to the development of electrowelded wire mesh, thus making the implementation step of any construction work fast and easy and reducing jobsite costs. The Pittini Group is the main manufacturer of electrowelded meshes in Italy. Thanks to 3 facilities based on the Italian territory, to over 60 years of experience and to consistent investments aimed at constantly improving the technological base of its plants, the Pittini Group offers high quality products.

The facilities of the Pittini Group manufacture a wide range of electro-welded meshes from high quality HD (High Ductility) steel, whose properties are guaranteed by stringent checks performed throughout the manufacturing cycle starting from careful inspection of scraps (raw materials). Thanks to its extensive sales network, widespread commercial and technical assistance is guaranteed. In addition, the Pittini Group’s manufacturing sites also produce customized meshes according to customer specifications.

Download technical sheet Meshes in Italy

The electrowelded wire meshes produced in Osoppo obtained the EPD Certification – Environmental Product Declaration – by the certifying partner ICMQ, the Institute for certification and quality branding for products and services for construction.

Italian Standard Electrowelded Meshes

| Steel grade | Country | Certification Body | Standard |

B450A |

Italy | STC Cons. Sup. Lav. Pubbl. | D.M. 17/01/2018 |

B450C |

Italy | STC Cons. Sup. Lav. Pubbl. | D.M. 17/01/2018 |

REMARKS:

– Identification mark 4/7 for the plant of Osoppo

Standard Meshes

| Mesh Type | Steel Grade |

Ø long. |

Ø trasv. |

mesh long. |

mesh trasv. |

Panel dimension | Weight/panel | Pcs/Bundle | |

| [mm] | [mm] | [cm] | [cm] | [cm] | [Kg] | ||||

510 2×3 |

B450A |

5 | 5 | 10 | 10 | 200×300 | 18.48 | 50 | |

510 |

B450A |

5 | 5 | 10 | 10 | 225×400 | 28.03 | 50 | |

515 2×3 |

B450A |

5 | 5 | 15 | 15 | 200×300 | 12.63 | 50 | |

515 |

B450A |

5 | 5 | 15 | 15 | 225×400 | 18.60 | 50 | |

520 2×3 |

B450A |

5 | 5 | 20 | 20 | 200×300 | 9.24 | 90 | |

520 |

B450A |

5 | 5 | 20 | 20 | 225×400 | 14.32 | 90 | |

610 HD 2×3 |

B450C |

6 | 6 | 10 | 10 | 200×300 | 26.64 | 50 | |

610 HD |

B450C |

6 | 6 | 10 | 10 | 225×400 | 40.40 | 50 | |

615 HD 2×3 |

B450C |

6 | 6 | 15 | 15 | 200×300 | 18.20 | 50 | |

615 HD |

B450C |

6 | 6 | 15 | 15 | 225×400 | 26.81 | 50 | |

620 HD 2×3 |

B450C |

6 | 6 | 20 | 20 | 200×300 | 13.32 | 50 | |

620 HD |

B450C |

6 | 6 | 20 | 20 | 225×400 | 20.65 | 50 | |

810 HD |

B450C |

8 | 8 | 10 | 10 | 200×300 | 47.40 | 50 | |

815 HD 2×3 |

B450C |

8 | 8 | 15 | 15 | 200×300 | 32.39 | 50 | |

815 HD |

B450C |

8 | 8 | 15 | 15 | 225×400 | 47.70 | 30 | |

820 HD 2×3 |

B450C |

8 | 8 | 20 | 20 | 200×300 | 23.70 | 50 | |

820 HD |

B450C |

8 | 8 | 20 | 20 | 225×400 | 36.73 | 50 | |

1020 HD 2×3 |

B450C |

10 | 10 | 20 | 20 | 200×300 | 37,02 | 50 | |

1020 HD |

B450C |

10 | 10 | 20 | 20 | 225×400 | 57.38 | 25 | |

1220 HD |

B450C |

12 | 12 | 20 | 20 | 225×400 | 82.58 | 25 | |

520L |

B450A |

5 | 5 | 19 | 25 | 118×600 | 10.83 | 90 | |

520B |

B450A |

5 | 5 | 20 | 20 | 247×600 | 23.42 | 50 | |

On request is possible to produce customised meshes and/or design to meet specific requirements of legislation or special computing needs.

On request electro-welded meshes up to diameter of 24mm can be produced.

Chemical Composition of Meshes B450A and B450C

| Limits | C % | P % | S % | Cu % | N % | Ceq % | |

PITTINI |

max | 0.22 | 0.050 | 0.050 | 0.80 | 0.012 | 0.50 |

D.M. 17/01/2018 |

max | 0.22 | 0.050 | 0.050 | 0.80 | 0.012 | 0.50 |

REMARKS:

– C: 0.25% max is admitted if Ceq max is 0.48%

Mechanical and size characteristics of meshes B450A

| Standard | Ø [mm] |

Weight Tol. [%] |

Re min [MPa] |

Re max [MPa] |

Rm min [MPa] |

Rm/Re min |

Rm/Re max |

Agt min [%] |

Rt min [%] |

PITTINI |

5÷10 | note | 450c | 563c | 540c | 1.05c | 1.35c | 2,5c | 25 |

D.M. 17/01/2018 |

5÷10 | note | 450c | 563c | 540c | 1.05c | 1.35c | 2,5c | 25 |

Mechanical and size characteristics of meshes B450C

| Standard | Ø [mm] |

Weight Tol. [%] |

Re min [MPa] |

Re max [MPa] |

Rm min [MPa] |

Rm/Re min |

Rm/Re max |

Agt min [%] |

Rt min [%] |

PITTINI |

6÷16 | note | 450c | 563c | 540c | 1.15c | 1.35c | 7,5c | 25 |

D.M. 17/01/2018 |

6÷16 | note | 450c | 563c | 540c | 1.15c | 1.35c | 7,5c | 25 |

NOTE:

– c characteristic val.

– Tests after artificial aging at 100°C/1h

– Weight tolerances: ± 4.5% for diameters larger than 8 mm; ± 6% for diameters up tp 8 mm

Gallery

Sales Organization

A continuous and reliable service is guaranteed by Pittini Group’s Sales Department.

Contact our designated representative: