Maplat System

Table of content

The product

The Maplat® system is the solution provided by Pittini to industrialise and rationalise reinforcements for large surfaces. The Maplat® system is made of made-to-measure electro-welded panels (both unidirectional and bidirectional, flat and/or shaped). This system makes on-site assembling and laying of reinforcements for structural elements faster and more rational with large savings on time and costs compared to traditional systems.

Maplat® electro-welded panels are manufactured by modern automatic electro-welding plants from bars of various diameters arranged at variable distances in both directions according to design requirements so that the product suits all applications.

The Maplat®system ensures:

- faster on-site assembling and simpler laying of reinforcements,

- savings on time and labour,

- highly accurate laying: reinforcements are always spaced according to design requirements and this considerably reduces laying errors.

Thanks to its versatility, this product can be used for all applications, from tunnels to residential buildings, to create:

- concrete bed foundations

- reinforced concrete monolithic or lightened floors

- cross walls

- bent joint

Furthermore, not only reinforcing bars can be obtained, but also joining brackets, closing brackets, connections and local reinforcements such as punching shear reinforcements.

All electro-welded reinforcements are manufactured according to European regulatory requirements (UNI EN 1992:2005 – Eurocode 2) and Technical Building Rules (Ministerial Decree 17/01/2018).

Maplat System elements

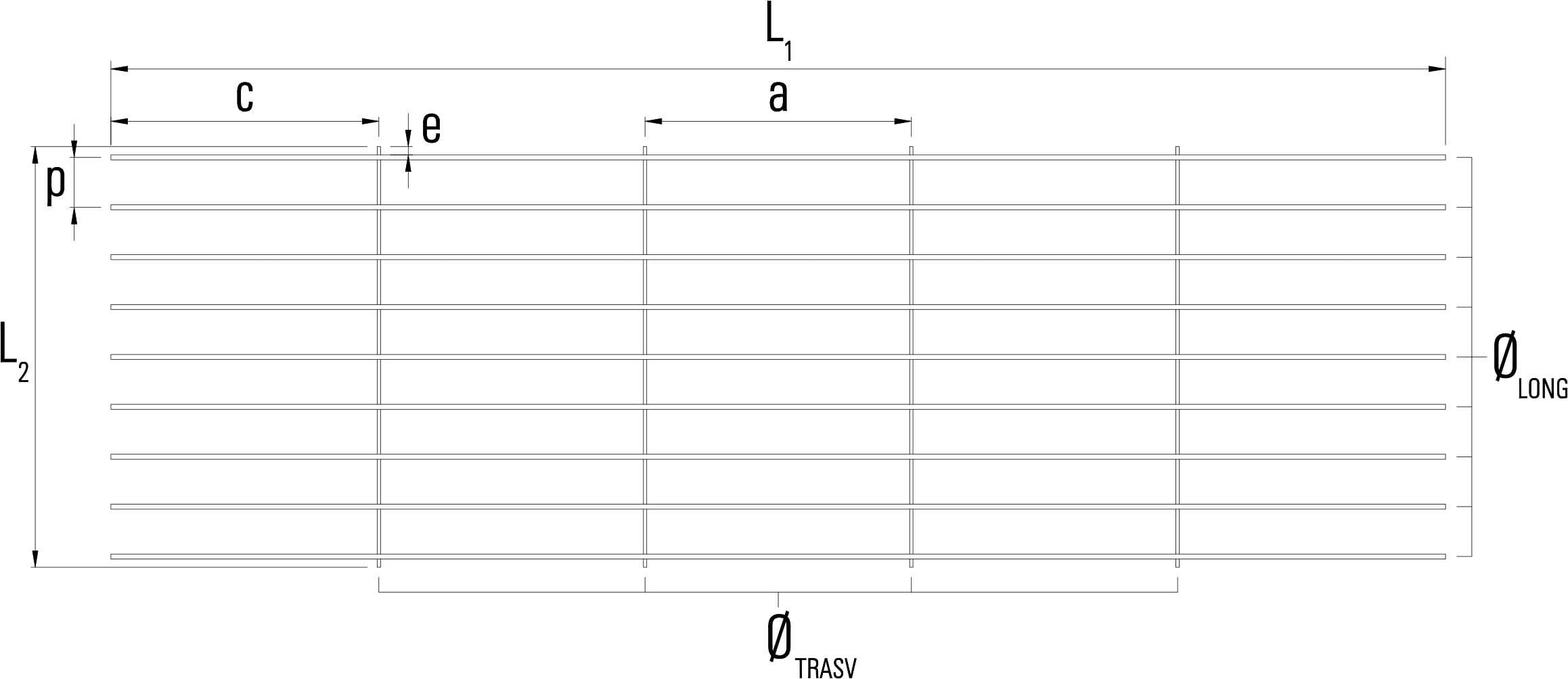

Maplat® unidirectional panels are unidirectional flat electro-welded meshes obtained from longitudinal steel rods (B450C and/or B500B) with variable length, diameter and distance according to design requirements. Transversal steel wires with reduced diameter and large openings are used for connections.

They are mainly used for general reinforcement of floors and beds where fast and rational laying of large panels up to 13 m long ensures huge savings on time and materials. Overlaps are limited to the longitudinal direction of panels.

Panels are laid in one direction only (they are juxtaposed transversally with no lateral overlaps). Then they are only overlapped longitudinally according to design and regulatory requirements. Thereafter, following the same principles, additional panels are laid along the main orthogonal direction. In this way, the lower reinforcing layer is obtained. The same procedure is applied to obtain the upper layer of the structural element.

Thanks to this system, any surface, regardless of its extension, can be rapidly reinforced. Up to 1,000 sq. m. of floor per day can be laid according to the complementary reinforcements to be added to the work.

Owing to its multiple advantages, the Maplat® system was chosen to rebuilt some areas hit by the earthquake in Abruzzo, namely to lay the reinforcements of beds and decks for the “C.a.s.e. – Sustainable and eco-compatible seismically sage complexes” project.

Maplat System® elements: spacers

Spacers arranged in rows at a distance of about 1 one from the other for the length required by the structural element ensure proper laying of floor and bed reinforcements and compliance with design thickness of concrete cover to reinforcement. They ensure:

Spacers arranged in rows at a distance of about 1 one from the other for the length required by the structural element ensure proper laying of floor and bed reinforcements and compliance with design thickness of concrete cover to reinforcement. They ensure:

-

- fast and simple laying

- stability and strength to bear loads resulting from the presence of operators

- accurate laying

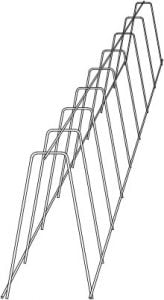

Maplat System® elements: punching shear

Punching shear Maplat® meshes are U-shaped meshes with transversal wires arranged so as to ensure fast and simple laying. They perfectly match all the other elements of the Maplat® system to ensure an effective and practical solution to the issue of shear stresses at cross walls and pillars.

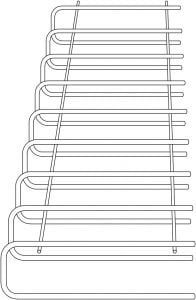

Maplat System® elements: joining and closing reinforcements

These meshes are made of U-shaped or L-shaped unidirectional electro-welded panels according to design requirements.

Longitudinal closing or joining brackets are arranged according to the distance provided for by design requirements and are connected by transversal electro-welded wires that serve as bracket support bars on one side of the contour only so as to ensure simple assembling with the other elements of the Maplat® system.

They are used as closing or joining elements for horizontal and vertical reinforcements.

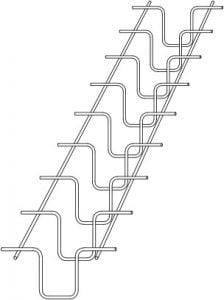

Maplat System® elements: meshes for cross walls

Meshes for cross walls are bidirectional electro-welded meshes with variable tails in both directions to ensure proper transversal and longitudinal overlapping of panels.

Vertical and horizontal wire diameters, distances and lengths can be adjusted to any design requirement.

Vertical Maplat® panels are used as reinforcements for reinforced concrete cross walls and structural elements intended for the absorption of seismic actions. Panels are juxtaposed and overlapped at tails, thus reducing the overall size of traditional overlapping panels.

Sales Organization.

A continuous and reliable service is guaranteed by Pittini Group’s Sales Department.

Contact our designated representative: